Keywords: General industrial equipment, Road construction equipment and machinery

The EPS automatic shape moulding machine has a variety of specifications and models. The working principle is basically the same. They all use hydraulic system and PLC control program. The pre-expanded and matured EPS beads are loaded into the mold cavity, and the steam heating system is used to make the steam directly enters the cavity through the pores of the mold wall, so that the beads soften and expand after being heated. Due to the limitation of the mold cavity, the expanded beads can fill the entire mold cavity of the device, thereby completely bonding as a whole. After cooling and shaping, the equipment can be opened to take out the product.

Features and advantages of products:

1、Energy saving: The ordinary light shape moulding machine produce 1 ton light board at the density of 4 kg/M3 needs 4.4-5.5 tons of steam. Our machine saves 30-50% of energy to produce light board, and it just needs 2-2.5 tons of steam on average.

Pipes and steam holes: Specially designed pipes and steam holes can save energy.

Heat preservation: the heat preservation design of the outer door panel, better heat preservation, saving heat energy, balanced temperature in the board machine, and better product quality.

2、The plate has fast forming speed, good adhesion and uniform density which can reach 6-45kg/ m3.

3、The machine can be equipped with touch screen, automatic conveying device, automatic electronic weighing and printing device.

4、The machine can be matched with color steel sandwich panels to produce 850mm, 950mm and 1150mm, as so as 1000mm building plates.

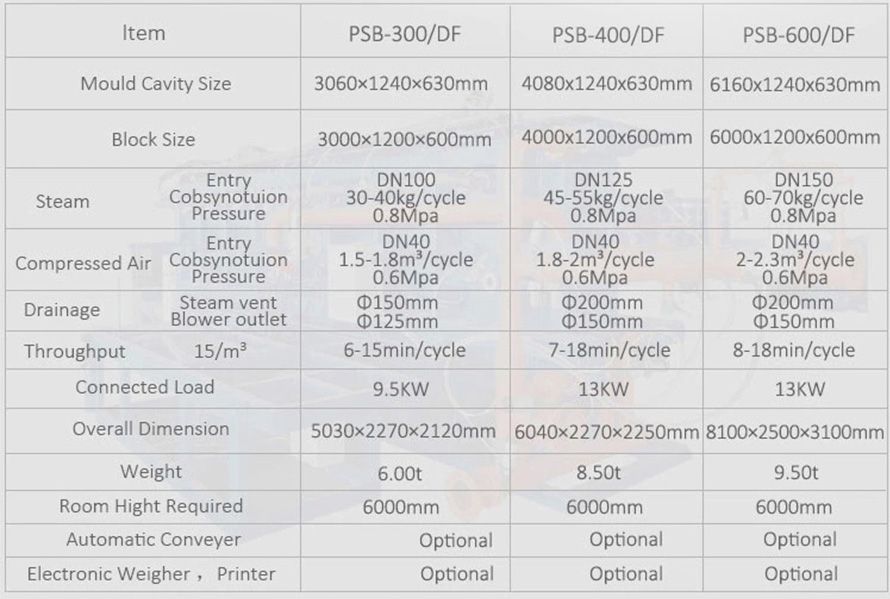

product parameter: